Neue Materialien Bayreuth GmbH worked with partners on a cooperation project to develop a new type of lightweight construction concept for aircraft construction. Nature provided the underlying idea – the researchers found the material and process solutions for technical implementation. Weight reduction is the central approach to eco-efficient flying. The aim of the project was therefore to create an innovative lightweight construction concept as a prerequisite for more sustainable air transportation.

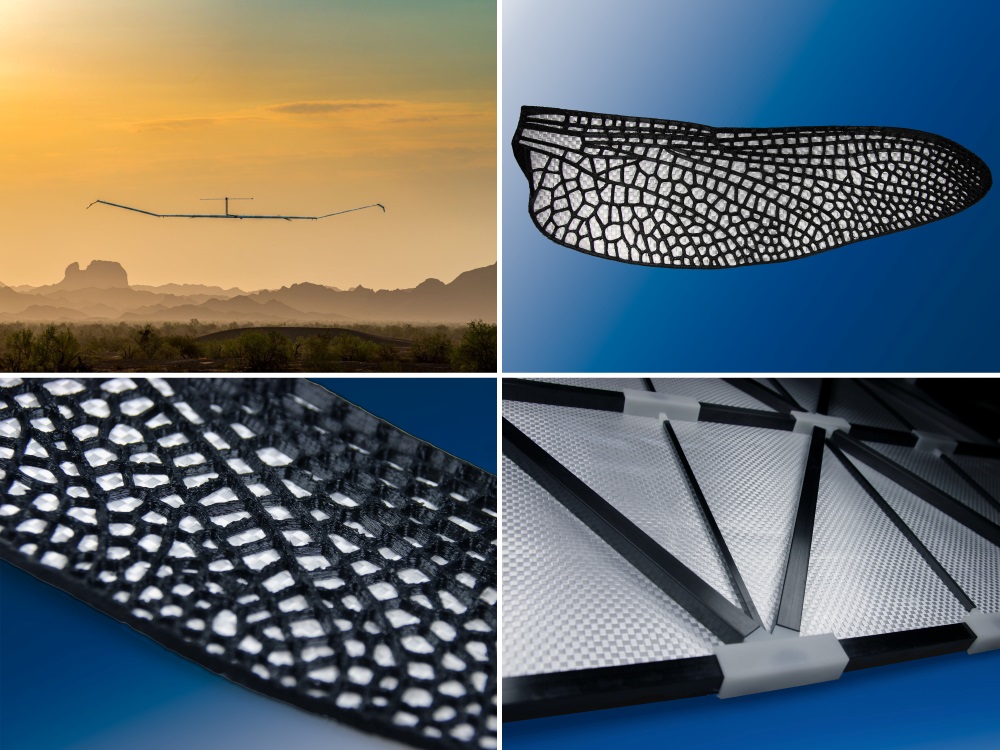

The bionic principle of a dragonfly wing was used as a model and inspiration from nature. The lightweight construction concept of such a wing consists of a thin membrane interspersed with a load-optimized, delicate network of wires. The transfer of this principle from nature to aerospace is particularly important for the development of new aircraft, such as slow-flying aircraft like the Zephyr, or in urban air mobility. The result of the project is a new type of structural design based on a hierarchically reinforced, pre-stressed membrane solution. This consists of a stiffening structure made of load-optimized carbon fibre-reinforced profiles (grid structure), which are bonded to a prestressed membrane (skin structure).

Careful selection of materials

In order to select potentially suitable membrane materials, their characterization was essential. These assessments were carried out by Airbus Defence and Space GmbH on the basis of tensile tests and mechanical impact tests in a pre-stressed biaxial state. In order to be able to represent special loads, such as hailstorms during the flight phase, a customized and specially developed test rig was set up in cooperation with Neue Materialien Bayreuth GmbH (NMB). The third work phase dealt with the influence of the applied reinforcements, which were designed hierarchically on the basis of real flight loads, on the membrane material. In order to evaluate this influence, the membrane materials reinforced with CFRP profiles were characterized. Parametric studies were carried out to investigate the impact behavior with different biaxial prestressing and impact energy.

A best choice was carried out after each work phase in order to reduce the number of samples in the course of the development work. The tests required for this served to validate the numerical modeling and simulation of the “Robust Skin”, which were carried out by the Chair of Carbon Composites at the University of Munich.

Picture above: Ultralight, unmanned aircraft of the Zephyr type (© AIRBUS); replica dragonfly wing and detailed view; demonstrator of the developed structural design consisting of grid and skin structure. Illustration: NMB