Recycling plastic waste to make our consumption more resource-efficient and sustainable makes sense both ecologically and economically. In addition, legal obligations require the proportionate use of recycled plastics in technical components. In the new project “Reliable use of recycled plastics in technical components”, the Fraunhofer Institute for Structural Durability and System Reliability LBF is working with partners to examine the fundamental interactions between material flow, processing and long-term behavior in highly stressed applications. The aim is to make products more sustainable and durable and to use more recycled plastics reliably in technical applications.

In technically demanding applications, recycled plastics have so far only been used with caution, as they have different material properties to virgin plastics and their long-term durability is not sufficiently known. These conditions are due to previous damage and contamination from the previous application as well as mixing effects of different material flows. In order to be able to use recycled plastics reliably in technical applications, a basic understanding of these relationships and methodical approaches for taking these influencing variables into account in component design are a basic prerequisite. OEMs and manufacturers of plastic components in the automotive, commercial vehicle and white goods industries often have very incomplete knowledge of these fundamentals.

Influencing factors for reliable plastic recyclates

One driving question, for example, is how to deal with batch fluctuations, as larger scattering ranges in the mechanical characteristic values lead to greater probabilities of product failure and, in the worst case, are relevant to safety. Therefore, these must be taken into account in the design of components.

This is currently leading to higher safety factors and the associated higher wall thicknesses, which counteract lightweight construction and thus economy and ecology. Furthermore, the behavior under long-term loading in highly stressed applications and possible changes in material behavior due to external influences is not sufficiently known. These characteristics must be taken into account when verifying a product in order to reliably estimate the product service life of a component.

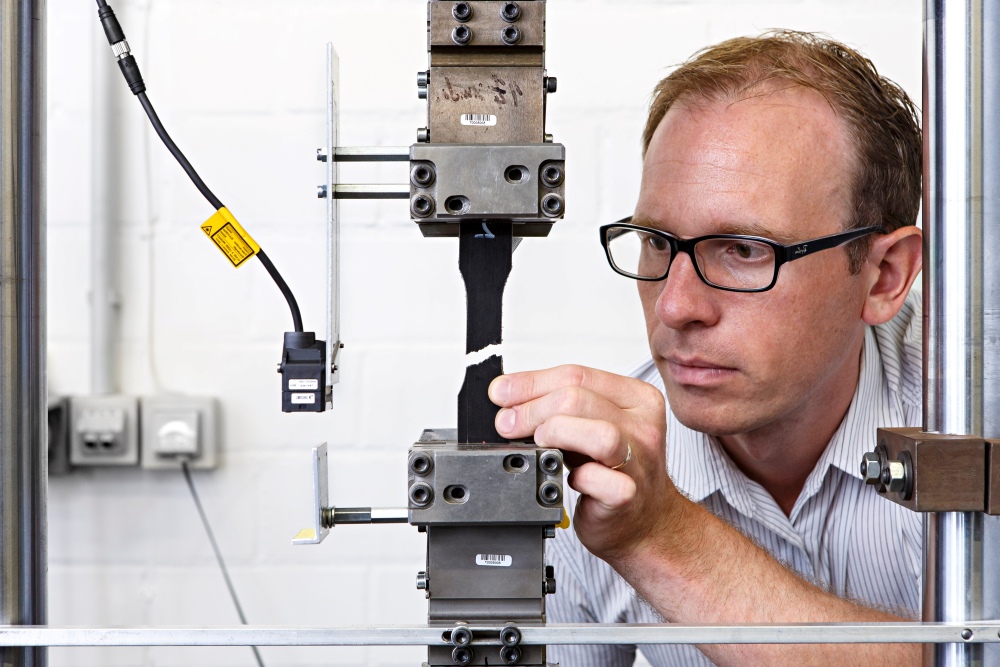

This is precisely where the new industrial joint project will come in and investigate two different recycled materials as examples. This can be rPP or rPA, for example, and depends on the requirements of the network participants. “The tests are carried out in parallel on equivalent virgin material to enable a direct comparison of recycled and virgin material,” explains Dominik Spancken, Germany’s first doctor of sustainability sciences and a scientist at Fraunhofer LBF.

Staying competitive: Estimating the shelf life of recycled materials

The project partners will be able to assess the challenges and potentials of using recycled plastics and derive the necessary material tests for the qualification of recycled plastics. With the knowledge gained, they can adapt their own dimensioning methods for component design in order to design technical components made from recycled materials for operational reliability. They can formulate their requirements more specifically to material manufacturers in order to achieve a higher degree of reliability. This joint project is aimed at companies along the value chain, from the granulate to the finished component and recycling.

Project partners from industry wanted

The project is open to further partners from industry and business. Interested parties can find details on the focal points and the next steps here.

Picture at the top: Sustainability expert Dominik Spancken wants to enable industrial partners from the plastics industry to better assess the potential of recycled plastics so that more technical components made from recycled materials are used. Photo: